Saturday, three volunteers continued the reconstruction of the Diamond and Caldor Railbus No. 10.

Steve Karoly,

Keith Berry and

Wayne Thorley, put in a full day. Steve and Keith supported Wayne as he welded new roof supports into the frame.

Our goal is to return the motorcar back to its 1953 configuration.

The

Tally Ho -- its affectionate name from its glory days in the 1930s and 40s -- was reconfigured sometime between 1953 and the mid-1960s by then owner Hal Wilmunder. He added the outside walls and reconfigured the windows on the cab/housing.

The railbus was lettered as the Camino, Cable and Northern No. 10 and worked on Wilmunder's tourist railroad from 1964 to 1974.

Richard Wright, pictured in the "fireman's seat," recently shared this picture of the railbus and two Shay locomotives in Camino. It was taken in May 1970.

The Shay on the right is the Diamond and Caldor No. 4. Wilmunder moved it from the fairgrounds to Camino in the fall of 1966.

"Friday morning (September 30, 1966) the old Caldor Shay engine at the fairgrounds was moved to the Camino, Cable and Northern railroad yards at Caimno, where it will be put back in operating condition and used on the narrow gauge line," said the October 6, 1966 issue of the

Mountain Democrat.

In the end, the Shay was not renovated and was returned to the fairgrounds placed back on display.

Sam Thompson steadily carves the middle eccentric for the Diamond and Caldor Shay No. 4 out of a large piece of cast iron. This photo, taken on Saturday, January 10, 2009, shows Sam's early progress. As of this past Saturday, the eccentric was starting to take shape. I'll post a photograph next week.

Sam Thompson steadily carves the middle eccentric for the Diamond and Caldor Shay No. 4 out of a large piece of cast iron. This photo, taken on Saturday, January 10, 2009, shows Sam's early progress. As of this past Saturday, the eccentric was starting to take shape. I'll post a photograph next week.

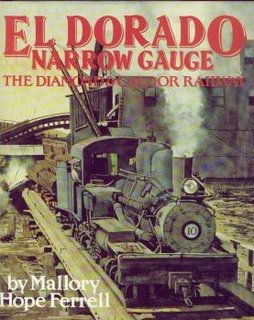

If you've followed this blog for any time, you know that we post several eBay auctions each year of our favorite book: Mallory Hope Farrell's El Dorado Narrow Gauge: The Diamond & Caldor Railway, which was published in 1990 (Pacific Fast Mail, Edmonds, Washington).

If you've followed this blog for any time, you know that we post several eBay auctions each year of our favorite book: Mallory Hope Farrell's El Dorado Narrow Gauge: The Diamond & Caldor Railway, which was published in 1990 (Pacific Fast Mail, Edmonds, Washington). "You check it again because it's easier to check than fix," said Keith Berry. Jacob has spent the morning assisting Keith to measure and cut the pieces for the battery box to the Diamond and Caldor Railbus No. 10. Once cut, Marcus Hodge will fabricate the box at his home shop.

"You check it again because it's easier to check than fix," said Keith Berry. Jacob has spent the morning assisting Keith to measure and cut the pieces for the battery box to the Diamond and Caldor Railbus No. 10. Once cut, Marcus Hodge will fabricate the box at his home shop.

Jacob cleans the edges on the piece of tubing for the coupler pocket. This ensures a clean surface when Wayne Thorley welds the piece in. And it gives Jacob a chance to learn how to control and use the grinder.

Jacob cleans the edges on the piece of tubing for the coupler pocket. This ensures a clean surface when Wayne Thorley welds the piece in. And it gives Jacob a chance to learn how to control and use the grinder.